Unfortunately, ASME VIII Div.1 doesn’t give a clear picture, whether to add the undertollerance in the min. required thickness as calculated by ASME VIII Div.1

ASME VIII Div. 2, give a clear cut understanding on this issue, can clears all ambiguity. (Clause 4.1.3)

The explanation goes as under

Mill Under tolerance. Plate material shall be ordered not thinner than the minimum required thickness.Vessels made of plate furnished with an under tolerance of not more than the smaller value of 0.3 mm (0.01 in.) or 6% of

the ordered thickness may be used at the full maximum allowable working pressure for the thickness ordered. If the specification to which the plate is ordered allows a greater under tolerance, the ordered thickness of the materials shall be sufficiently greater than the design thickness so that the thickness of the material furnished is not more than the smaller of 0.3 mm (0.01 in.) or 6% under the design thickness.

{The underline sentence is very clear, if they are in this limit, no need to add the allowance in calculation, which as per II-A, need to be part of purchase specification, and purchaser has to bid by it}

Pipe Under tolerance. If pipe or tube is ordered by its nominal wall thickness, the manufacturing under tolerance on wall thickness shall be taken into account. After the minimum wall thickness is determined, it shall be iincreased by an amount sufficient to provide the manufacturing under tolerance allowed in the pipe or tube specification.

{Again, this is very clear, we need to take this in account in our calculation}

So, Bottom line

If the shell is made from Plate (Rolled) and if purchase specs for Plate as per ASME II-A, then the vendor is binded to supply material within these limits, and we need not to consider additional allowance. But if your shell is made from Pipe, then you need to consider the 12.5% tolerance during calculation of thickness!

Hope this will help.

2. Tables for tube hole drilling have been expanded to 3” diameter tubes.

3. Guidelines for performing Finite Element Analysis (FEA) had been added.

4.Rules for the design of shell intersections (with large nozzle to cylinder ratios) subjected to pressure and external loadings have been added.

5.Foreign material cross-reference linking material specifications from various international codes has been added.

6.Rules for the design of longitudinal baffles have been added

Followings are my observation (And I’ll keep it upto date as more I go in detail)

1. Page numbering & Indexing changed completely

2. Tube Plate thickness calculation is now moved to Appendix A, and detail and simplified approach is seen.

3. Section T (Thermal Relations), Section P (Physical properties of fluids), Section D (General Information) and Section RGP (Recommended Good Practice) added

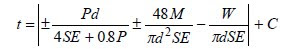

It is customary for most vessel designers to establish the minimum vessel shell and trend thickness according to the pressure temperature conditions and then calculate the thickness required at the bottom head seam due to bending moments imposed by wind or earthquake forces. Stresses in the longitudinal direction are involved nod the following notation may

be used to summarize the thickness required :

Here, The terms within the absolute value signs are positive for tensile stresses and negative for compressive stresses. The first term gives the thickness required for the longitudinal stress resulting from internal pressure and is positive for pressures above atmospheric and negative for pressures below atmospheric. The second term is the thickness required to resist the longitudinal bending stress and both positive and negative values exist at the same time. The third term is the thickness required for the weight of the vessel above the seam being investigated and, since this is a compressive stress, it has a negative value. The combination giving the highest value establishes the thickness required to resist the longitudinal stresses.

This formula hold good when the units are in Psi, ft & lb, if the units are in MPA, mm, N then remove the ’48’ from the formula.

External pressure can be due to internal negative Pressure, or external loading like wind, earthquake etc. or live load, snow load etc.

One can design Pressure vessel for either sever combination of various load or for most possible occurrence of load combination.

Load combinations are given in respective ‘Building Code’ like API, UBC, IS etc.

Yes, If you noticed I’ve said ‘Building Code’, why? as most of these loading decides how the pressure vessel, and if it fails, it can harm the occupants. hence design of such loading will be governed by building codes.

These Building code will give su way to calculate loading on tank/vessel, and then our design code like ASME, BS,EN will tell us how to derive the thickness from them.

one should note that, nearly all the design code talks about +ve Internal pressure & -Ve internal pressure & its design rules, but none of the code talk about how to do thickness calculation for the loads specified above.

In latest edition of ASME it does talk about these loading, and ask user to use Engineering practices to calculate loadings (UG-22), loading listed in this sections are

(a) internal or external design pressure (as defined in UG-21);

(b) weight of the vessel and normal contents under operating or test conditions;

(c) superimposed static reactions from weight of attached equipment, such as motors, machinery, other vessels, piping, linings, and insulation;

(d) the attachment of:

(1) internals (see Appendix D);

(2) vessel supports, such as lugs, rings, skirts, saddles, and legs (see Appendix G);

(e) cyclic and dynamic reactions due to pressure or thermal variations, or from equipment mounted on a vessel, and mechanical loadings;

(f) wind, snow, and seismic reactions, where required;

(g) impact reactions such as those due to fluid shock;

(h) temperature gradients and differential thermal expansion;

(i) abnormal pressures, such as those caused by deflagration;

(j) test pressure and coincident static head acting during the test (see UG-99).

In next section, we will discuss how to calculate final thickness of a vessel considering all loadings

We design pressure vessel for longitudinan and circumferencial stresses. Now whats that?

Ok, longitudinal stresses comes on circumferencial joints, where as circumferencial stresses comes on longitudinal joints.

And to add cherry on top circumferencial stresses are twise that of longitudinal stresses.

If you are not yet twisted your tongue, and to avoid that we generally call them c’seam and l’seam and c’stress and l’stress.

In below pictures, one can identify types of Seams and Stress.

here p is design pressure, R is internal Radius, L is Length of shell, t is thickness of shell.

Hence with the basic mechanical formula,

t for Hoop stresses = pL (2R)/2 xStressx L = pR/Allw. Stress

t Longitudinal stresses = px3.14xR^2 / (2×3.14xRxAllw. Stress) = PR/2 Allw. Stress

& what ASME Says..

t for Hoop Stress = PR/(SE – 0.6P)

Where S > All. Stress, E > Joint Eff. or factor of safety

why 0.6 P, because, its factor of safety set by ASME People

&

t for Longitudinal Stress = PR/(2SE+0.4P)

Note the ‘2’ in denominator..

if E remain the same for both cases, then thickness given by Hoop stress will be twice that of by Longitudinal stresses

For Calculation Sheet Visit http://sumitmechsoftware.blogspot.com/

OK..

The Billion dollar Question…

Just to make it easy, we will break the pressure vessel in two category..

1. Pressure Vessel without external loading &

2. Pressure Vessel With external Loading

For Category 1, we can use ASME Section VIII Div. 1 directly, where as for Category 2, we need to consider additional loadings. And for additional loading we need to follow the basic engineering practices.

Hence, in future section, 1st we will discuss the Sizing of Pressure vessel as per ASME Section VIII Div. 1, and then we discuss the additional loading part.

Failure: Failure of a structure is an event, the transition from a normal working state, where the structure meets its intended requirements, to a failed state, where it does not meet its requirements

Limit states: A limit state is a structural condition beyond which the design performance requirements of a component are not satisfied. Limit states are classified into ultimate limit states and serviceability limit states

Elastic limit states: An elastic limit state is a structural condition associated with the onset of plastic deformation. This term is usually used in connection with monotonic actions, and it relates to virtual structures, usually with zero initial stress distribution

OPERATING PRESSURE : The pressure which is required for the process, served by the vessel, at which the vessel is normally operated.

DESIGN PRESSURE : The pressure used in the design of a vessel. It is recommended to design a vessel and its parts for a higher pressure than the operating pressure. A design pressure higher than the operating pressure with 30 psi or 10 percent, whichever is the greater, will satisfy this requirement, The pressure of the fluid and other contents of the vessel should also be taken into consideration.

MAXIMUM ALLOWABLE WORKING PRESSURE : The internal pressure at which the weakest element of the vessel is loaded to the ultimate permissible point

HYDROSTATIC TEST PRESSURE : One and one-half times the maximum allowable working pressure or the design pressure to be marked on the vessel when calculations are not made to determine the maximum allowable working pressure.

There are many more terms than this… but to start with.. these are sufficient.

Pressure vessels are probably the most widespread “machines” within the different industrial sectors. In fact, there is no factory without pressure vessels, steam boilers, tanks, autoclaves, collectors, heat exchangers, pipes, etc.

More specifically, pressure vessels represent components in sectors of enormous industrial importance, such as the nuclear, oil, petrochemical, and chemical sectors.

There are numerous Codes & Laws present in each country to control the usage of this ‘machines’! its useful but its dangerous!

What one need to design a Pressure Vessel?

● good workmanship with regard to the tools used,

● knowledge of the basic engineering principles and the phenomena involved,

● fantasy and creativity with regard to the selection of the models used,

● fair knowledge of the legal requirements pertaining to design,

● fair knowledge of manufacturing and testing procedures, and especially

● extreme carefulness in each step, from the design specification to the design

report.

Pressure Vessel mostly are made-up of ‘Steel’ Steel behaves in an elastic fashion even beyond the proportional limit, as long as another characteristic point corresponding to stress called elastic limit is not exceeded.In practice, we typically equate the proportional limit to the elastic limit.

we always discuss the steel’s behavior at room temperature. It is, however, of the greatest importance to be aware of the influence of temperature on the mechanical characteristics of the material. As we shall see, not only temperature but also time may have a strong influence.

Next we will discuss some “TERMS”

The differences have to be taken into consideration by both designer and welder. The high thermal expansionand low thermal conductivity of the austenitic steels lead to higher shrinkage stresses in the weld thanwhen carbon and ferritic steels are used. Thin sections of austenitic steels may therefore be deformed when an abnormally high heat input is used

These steels are mainly used in wet environments. Withincreasing chromium and molybdenum contents, the steels become increasingly resistant to aggressive solutions. The higher nickel content reduces the risk of stress corrosion cracking. Austenitic steels are more or less resistant to general corrosion, crevice corrosion

and pitting, depending on the quantity of alloying elements.

Resistance to pitting and crevice corrosion is very important if the steel is to be used in chloride-containing environments. Resistance to pitting and crevice corrosion increases with increasing contents of chromium, molybdenum and nitrogen.

In pressure Part Industry we use various type of material.

Typically in industry like this, we mainly classify material as Mild Steel also known as Carbon Steel, we also use low & high alloy steel & yes stainless steel!

What diffrentiate staineless steel from Carbon steel is its corrosion resistance properties, whcih comes because of its alloy elements.

In my blog hence onward, we will discuss about the material of constrution that we use in this industry.

I’ll come back soon.