Yup, just a brief on this subject.

Heat exchangers are devices used to transfer heat energy from one fluid to another, gas to gas or gas to liquid.

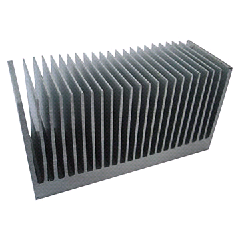

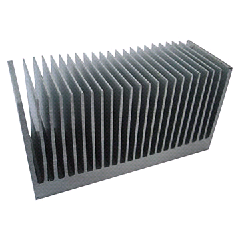

Typical heat exchangers are seen around in most unexpected location. From household appliances as air conditioners, refrigerator etc. Boilers and condensers in thermal power plants are examples of large industrial heat exchangers. There are heat exchangers in our automobiles in the form of radiators and oil coolers. Heat exchangers are also abundant in chemical and process industries.

Heatexchanger sizes varies from couple of square mm (heat sink in computer cpu) to length exceeding hundreads of square meters!

From simple study flow to complex flows.

Heat exchanges as they say “comes in all sizes and nearly for all duties”

We will, in my next post discuss about fundamental of heat exchangers.

Design of heat exchanger step :3 : Estimate

Generally we can get reference from various resources listed below, either expected heat flux (W/m2) or range of heat transfer co-efficient. based on this information, we can estimate the heat transfer area required.

But if the case is, you are doing for first time, and have no earlier experience in that type of heat exchanger, then better is make your self ready with all information e.g fluid properties which includes

The grate equation (you can see in my earlier post) for heat duty is:

Q = U A LMTD & Q = m. cp. DT

where

Q = heat duty (kcal/hr)

U = over all heat transfer co-efficient (Kcal/hr.m2.oC)

A = heat transfer area (m2)

LMTD = Log mean temperature (degC)

cp = Specific heat of the fluid to be heated / or to be cooled (kcal/kg)

DT = temperature difference of any one of the fluid (degC)

m = mass flow rate of the fluid (kg/hr)

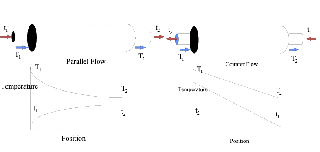

LMTD is calculated based on the temperature on both the side for both the fluid

it’s simple if you understand the following figure

& LMTD = (dto – dti) / ln(dto / dti)

Just Plot your temperature, take difference on each side, and do the arithmatics…

Some good refrences (Free google search results 🙂

http://www.chemsof.com/lmtd/lmtd.htm

http://en.wikipedia.org/wiki/Log_mean_temperature_difference

http://www.wlv.com/products/databook/databook.pdf